Notre gamme de robots industriels à grande vitesse, à la pointe de la technologie, compte plus d'une centaine de modèles pour répondre à tout type d'application. Elle comprend des robots spécifiques à forte capacité, à portée étendue, des robots 7 axes extrêmement agiles, des robots double bras à 15 axes ou encore des cobots.

HV600

The quality drive for commercial HVAC applications

Uniquely designed for building automation

Yaskawa Variable Frequency Drives (VFDs) deliver high quality, top-tier solutions that maximize building energy efficiency performance, saving you money.

High performance that pushes expectations

Building owners. Facility managers. Mechanical contractors specifying drives. They all trust Yaskawa to deliver reliable performance in HVAC applications. Yaskawa offers:

- Industry experience

- Quick commissioning

- Easy-to-use interface

- Quick delivery

- Product quality

Yaskawa has delivered great HVAC solutions for these customers since 1988. The HV600 family of drives pushes past industry requirements to establish a new benchmark for industry expectations. In fact, the HV600 addresses all of the most pressing demands, including more flexibility and control, less downtime and more packaging options.

Exceeding your expectations

More than a quarter million installed Yaskawa VFDs reliably save energy and supply fresh air and water to the buildings we use every day.

Office buildings are probably the most common type of facility that benefit from using Variable Frequency Drives. But many other buildings can benefit from the energy savings and carbon footprint reduction provided by VFDs, including:

- Data centers

- Educational facilities

- Entertainment venues

- Government facilities

- Housing developments

- Medical facilities

- Parking structures

- Retail stores

A Yaskawa representative, or partner, can help you wherever usage can deliver the biggest return on your investment.

- Booster pumps

- Chiller compressors

- Chilled water pumps

- Condenser water pumps

- Condensing fans

- Cooling tower fans

- Fan arrays

- Supply and return fans

Variable frequency drives reduce energy use

A typical fan or pump running at 50% speed will use one-fifth as much energy compared to systems using mechanical control methods.

The primary reason VFDs reduce energy and improve system efficiency is due to the elimination of throttling, which has been the traditional method of mechanically adjusting air or water flow in a system. VFDs control the speed of fans, pumps and compressors.

Building owners can typically expect 20 - 70% energy savings when applying VFDs to fan and pump systems while creating a more comfortable work environment. VFDs are the perfect marriage between comfort and sustainability.

The HV600 family of VFDs also contributes toward LEED credits and help buidlings meet or exceed Energy Star Certification.

- Reduced mechanical and electrical stress on fan belts, compressors and pumps

- Reduction or elimination of demand charges

- Power factor improvement

- Control and monitoring via communication protocol

Capable. Efficient. Reliable. The new HVAC benchmark.

The Yaskawa Building Automation team is dedicated to listening to each of our different customer types to better understand each of their needs.

Building owners

Expect maximum customer comfort at minimal cost.

Facility managers

Expect simple maintenance, error free operation and specifications to be met.

Engineer's choice

Expect compliance to industry trends, customer acceptance, and quick and accurate commissioning.

Mechanical or electrical contractors

Expect easy installation and programming and quick response to any questions.

HVAC control contractors

Expect integrated control, stable software, and compatibility across various platforms.

Maintenance & service contractors

Expect to easily identify and quickly resolve problems by replacement or field maintenance.

25%

of electricity used in office buildings is for air handling systems

70%

less HVAC energy cost with VFDs

100%

commitment to provide best quality and service possible

Advanced HVAC features

Simple operation

- Real-time clock for scheduled functions

- Hand-Off-Auto keypad with LCD display and tactile buttons

- Timer controls for starting, stopping, and speed changes

Designed for building automation

- Built-in building automation protocols

- Compliance with global certifications and standards

- Built-in line impredance for harmonic reduction

- On-board EMC/RFI filter

- Conformal coating for circuit board protection

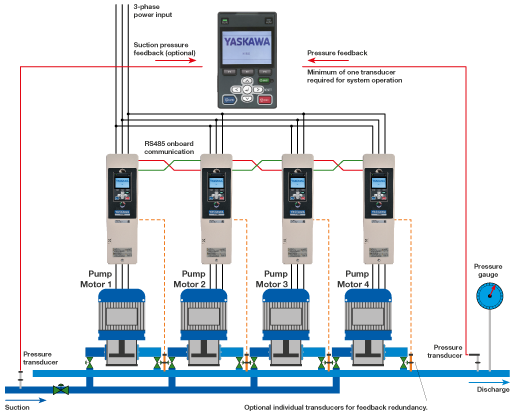

Network multiplexing

The HV600 has a special network multiplexing function that enables four drives to work in a closed-loop leadlag configuration.

You can program the drive using pump terminology for fast and easy set up. Pump protection features ensure maximum drive and pump life.

Emergency override

This function enables the drive to operate regardless of faults ensuring smoke clearance, preventing smoke infiltration, and providing fresh air in emergency situations to safeguard human safety.

Enhanced pump control

The HV600 includes intelligent pump control capable of single failure-proof booster pump control. It also has built-in deadhead protection, loss of prime detection, and many other pump system protection features. The HV600 protects your building.

Quick and easy set-up

- Simple steps for efficient commissioning

- DriveWizard® support tool for PCs

- DriveWizard® Mobile app for VFD management on smart mobile devices

- Safe programming without main three-phase power

- Side-by-side mounting for multiple drives to be installed in a minimal mounting space

- All models are plenum rated for building automation applications

Utility start delay timer

- Prevent a peak power surge when more than one drive powers up and accelerates at the same time

- Ensures that the power system is not stressed when utility power is restored and the pump system is restarted automatically

Sequence run timers

- Programmable run timers for Real Time Clock (RTC).

- Automatic start/stop of the drive at certain times without host control system

- Run timers daily, on weekdays, on weekends, or only on certain days of the week.

Low and high pressure feedback detection

The HV600 drive continuously monitors the system feedback to report a warning alarm or fault based on the programmed level.

Second PID controller

The drive's second PI controller option allows for automatic use of a secondary backup PID controller in the event of a primary PID controller failure. A text message on the keypad indicates which feedback PID controller is in use.

*See manual for specific VFD ratings

Overload capacity

- 110% for 60 s

- 140% for 2 s

Output frequency

- 0 ... 400 Hz

Control methods

- V/f control

- PM open loop vector control

- EZ vector control

Available I/O

- 7× MFDI, 2× MFAI

- 1× fault relay output, 3× MF relay output, 2× MFAO

- 2× safe disable input

- 1× 24 VDC control power input

Network communication

- Embedded: BACnet, Metasys®, Apogee®, Modbus®

- Optional: PROFINET®, PROFIBUS®, EtherNet/IP™

IP rating

- IP20 up to 302 A (160 kW)

- IP55 up to 156 A (75 kW)

- Built-in C2 filter

Application presets

- Fan

- Fan with PI Control

- Return Fan with PI Control

- Cooling Tower Fan

- Cooling Tower Fan with PI Control

- Pump

- Pump with PI Control

Downloads

Already know what you need?

If you already know what you need and just want to make sure we offer the perfectly sized HV600, go ahead to the drive configurator. You will also find the technical data and any downloads you might need - be it CAD files for designing your machine, manuals, CAE files, brochures or software.